Why do we need Bioplastics?

Plastics are an indispensable part of modern society with numerous everyday applications in packaging (40%), building (20%) and automotive (8%), among other industries. Plastics have countless social benefits in our daily lives. The population growth, economic progress, demand for commodities and lifestyle changes are remarkably increasing the demand and production of plastic products.

However, more than 330 million tons of plastic is produced worldwide every year. Conventional petrochemical-based plastics are non-biodegradable because of which they amass in landfills and oceans for thousands of years, where they either pile up emitting toxic greenhouse gases under anaerobic conditions, or are incinerated.

Direct incineration of municipal solid waste enriched with plastic wastes releases toxic pollutants such as furans, dioxins, polychlorinated biphenyls and mercury into the environment, increasing the risk of pulmonary and cardiac diseases, respiratory ailments, nausea, headaches, skin rashes, cancer, birth defects, endocrine disruption, compromised immunity and severe damage to the nervous and reproductive system in humans.

Plastics overtime break into microplastics, typically having size of < 5 mm. Due to their smaller size, these plastic particles can penetrate our food, soil, water and air. A recent report suggests that for the first time, microplastics are detected in the placentas of unborn babies, which is a matter of great concern.

Recycling is often pushed as a silver bullet for plastic pollution, but a study suggests that only 9% of plastics are being recycled. Even then, they have to be discarded after 2-3 cycles. Furthermore, improper waste management, high heterogeneity, non-cooperation and cross-contamination of plastic wastes with organic matter and inert materials typically make recycling costly, energy intensive, and inefficient.

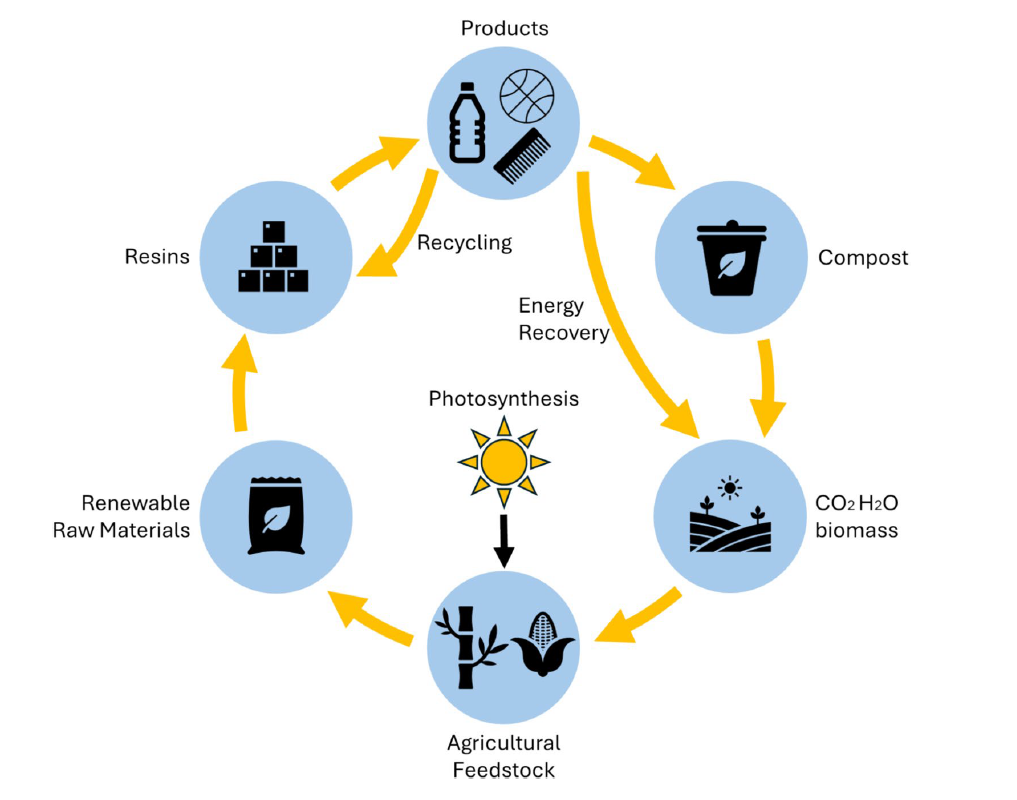

Hence, bioplastics were invented to mitigate this plastic crisis. Bioplastics are generally manufactured by utilizing natural renewable resources such as sugarcane, starch, algae, bio-waste, and cellulose, to make next generation functional biopolymers that can replace 90% of fossil-based plastics. They can be home or industrially compostable, thus sending them back to nature and closing the loop, which promotes a circular economy.

Bioplastics are innovative and sustainable materials that are designed to reduce environmental damage by decomposing into non-toxic components like water, CO2, and biomass in just a few months under right conditions, thus, reducing the risk of pollution in landfills and oceans.

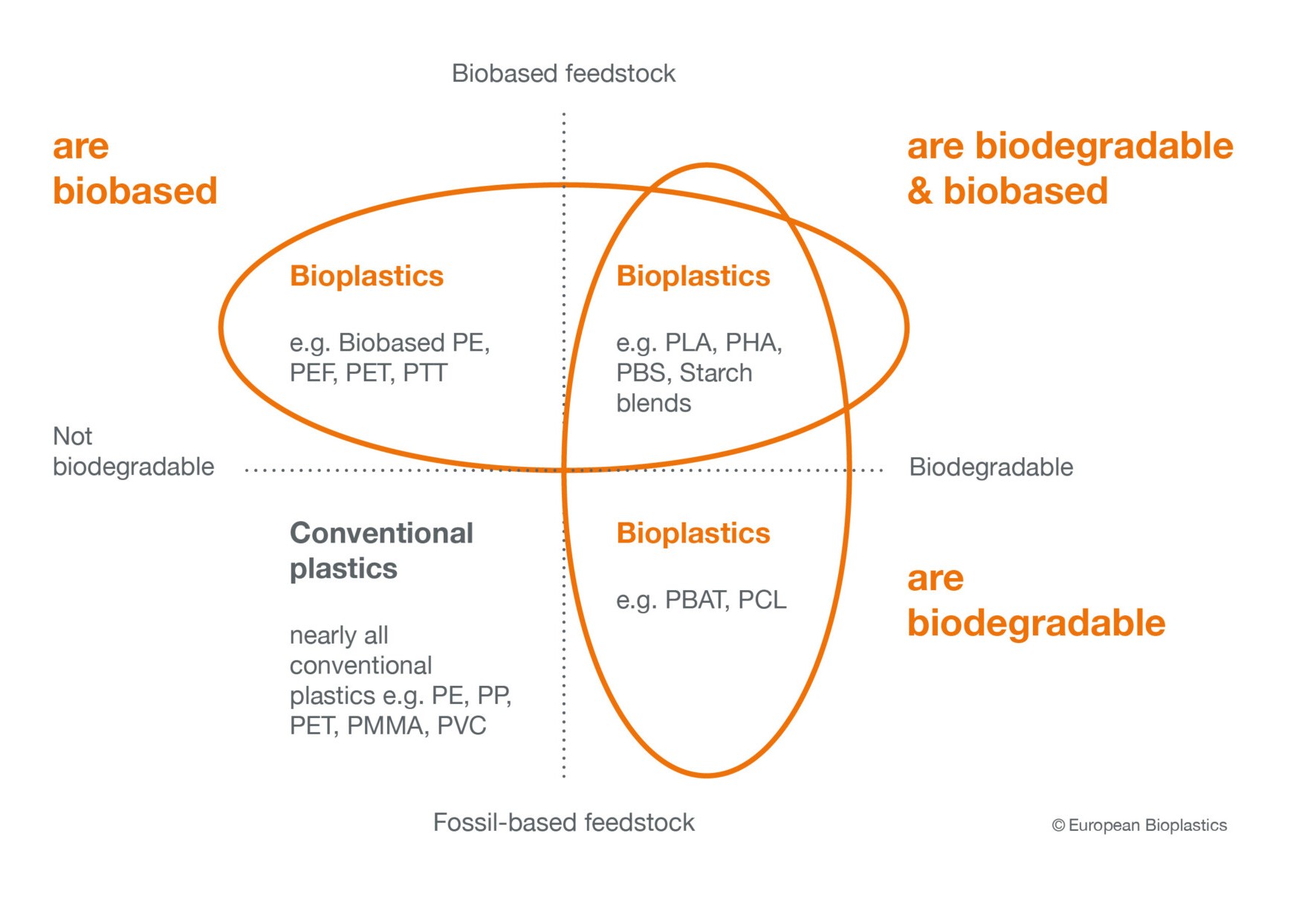

Bioplastic is essentially a type of plastic, a polymeric material that is either bio-based or is made from renewable materials with bio-degradability potential.

Why do we need Bioplastics?

Plastics are an indispensable part of modern society with numerous everyday applications in packaging (40%), building (20%) and automotive (8%), among other industries. Plastics have countless social benefits in our daily lives. The population growth, economic progress, demand for commodities and lifestyle changes are remarkably increasing the demand and production of plastic products.

However, more than 330 million tons of plastic is produced worldwide every year. Conventional petrochemical-based plastics are non-biodegradable because of which they amass in landfills and oceans for thousands of years, where they either pile up emitting toxic greenhouse gases under anaerobic conditions, or are incinerated.

Bioplastics are innovative and sustainable materials that are designed to reduce environmental damage by decomposing into non-toxic components like water, CO2, and biomass in just a few months under right conditions, thus, reducing the risk of pollution in landfills and oceans.

Types of Bioplastics

Although various types of biopolymers exist, there is often confusion in classifying them and understanding the specific advantages each type offers. Considering that bioplastics is still a nascent industry, the confusion around them is well justified. For instance, consumers often have ambiguity about biodegradable, compostable, and oxo-degradable plastics.

- Bio-based & Biodegradable Plastics

These are specific types of bioplastics, that are derived from renewable feedstock, and are also biodegradable. Biodegradable plastic refers to any material that will break down into its constituent components. Nearly every material will biodegrade given enough time, but what is important to note is whether it leaves behind toxic residues, and specifying environmental conditions it requires and the timeframe in which it decomposes. Which is why, claiming that a plastic is “biodegradable” without any further context is misleading to consumers. All compostable plastics are biodegradable, but not all biodegradable plastics are compostable. If an item is certified compostable, then it has been tested to completely breakdown. Example: PLA, PHBV, PHA, Starch Blends.

2. Fossil-based & Biodegradable Plastics

These bioplastics are similar to their bio-based counterparts, the only difference being that they come from fossil-based feedstock. They are both, biodegradable and compostable in nature, and have similar end-of-life properties, but rely on petrochemical resources. They are often blended with bio-based and biodegradable plastics to achieve a blend of functional and affordable compostable alternatives. Example: PBAT, PVOH, PCL

3. Compostable Plastics

Compostable plastics are specific type of biodegradable plastics that are designed to break down in 90 to 180 days in a commercial or a home composting facility, depending on the formulation. They are tested and certified accordingly by a third-party agency to adhere to strict international standards such as ISO 17088 (India), EN 13432 (Europe), and ASTM D6400 (USA).

As per these standards, the material passes through Disintegration, Aerobic Degradation, Compost Testing, and Heavy Metal Analysis tests, where they disintegrate within 90 days, and biodegrade at least 90% in 180 days in a standard composting facility without producing any harmful residue. Rest of the organic matter breaks down to become a pile of nutrient-rich soil, which can be used in gardening or farming. Example: PLA, PBAT, PHA, PHB, PBS

4. Bio-based & Non-Biodegradable Plastics

Commodity plastics like PE, PP, and PET can also be made from renewable resources, such as sugarcane or plant oil waste, but it does not degrade in any specific timeline. It behaves just like conventional plastics, and takes million years to disappear. The only advantage is that it is bio-based and hence it has a smaller carbon footprint. Examples: bio-PE, bio-PP, bio-PET

5. Oxo-Degradable Plastics

Oxo-degradable or degradable plastics are infact not bioplastics. They are nothing but petrochemical based non-biodegradable conventional plastics that are mixed with additives in order to make them break faster. While they break down into tiny particles known as microplastics, they do not decompose at the molecular or polymer level like biodegradable or compostable plastics, making them actually worse than traditional plastics.

Applications of Bioplastics

Bioplastics have tremendous potential to replace petroleum-based plastics across a wide range of applications, including green packaging solutions, biodegradable products for home use, consumer goods for eco-friendly corporate gifting, sustainable event supplies, and eco-friendly plates and bowls to name a few. Needless to say, sustainable product packaging alone accounts for 47% of the bioplastics market share.

| Industry | Applications |

| 🌿Packaging | Compostable bags, food trays, films, pouches, wrappers |

| 🚜 Agriculture | Mulch films, plant pots, seedling trays |

| 🩺 Medical | Sutures, drug carriers, tissue scaffolding, implants |

| 👕 Textiles | Biodegradable fibers, sustainable fashion |

| 🚗 Automotive | Dashboards, insulation, trims made from bio-composites |

| 📱 Consumer Goods | Biodegradable straws, cutlery, bottles, toys |

With such versatile applications one has to simply search “where to buy compostable products online” to find countless options that help reduce plastic waste effortlessly, because going green has never been easier – or more important.